Shaffer Bop Pod Manual

Book Descriptions: Shaffer bop pod manual is good choice for you that looking for nice reading experience. We hope you glad to visit our website. Please read our description and our privacy and policy page. How it works:. 1. Register a free 1 month Trial Account. Download as many books as you like (Personal use).

Shaffer bop pod manual - free eBooks download - - Shaffer bop pod manual download on Ebooke-zz.com free books and manuals search - Shaffer Bop Pod Manual.

3. Cancel the membership at any time if not satisfied. Note: We cannot guarantee that every book is in the library. But if You are still not sure with the service, you can choose FREE Trial service. You can cancel anytime. You can also find customer support email or phone in the next page and ask more details about availability of this book. Click 'CONTINUE' button to proceed.

Last Updated on Mon, 29 Oct 2018 1.16.1 Essential Knowledge As the indirect is the most common system in use on semi- submersible rigs, the examination focuses exclusively on this system. Therefore, it is necessary to be conversant with this type of control. In particular, the examination concentrates on the following:. Position of equipment in the control system. You should be familiar with the equipment shown in Figure 50 and be able to located specific items by name. You should also be able to determine where individual items are located such as SPM valves, shuttle valves, pod selector valves etc. Identifying which components are duplicated in the control system and which components have no duplication.

There are two SPM valves for each function (one in each pod) but only one shuttle valve. The sequence of events required to operate a particular function on the BOP. These sequences can be followed in Figure 51, Figure 53, Figure 54 and Figure 55. These should be understood and remembered. Knowledge of the pressure of fluids in particular systems. Rig air pressure, manifold pressure, accumulator pressure, annular closing pressure, pilot fluid pressure and power fluid pressure should all be familiar to you. Remember that pilot signals go to both pods every time whereas power fluid goes only to the active pod.

Sizing of accumulators should be understood. You should understand the reasons for locating the accumulators at the subsea stack. Understand the difference between float and bladder type accumulators. Methods used for trouble shooting problems such as leaks and malfunctions.

16.2 Introduction Every component in a assembly is operated hydraulically by moving a piston up and down or back and forth. Thus the function of a is to direct to the appropriate side of the operating piston and to provide the means for fluid on the other side of the piston to be expelled. On land, jack-up or platform drilling operations the control of the BOP is easily achieved in a conventional manner by coupling each directly to a source of hydraulic power situated at a safe location away from the wellhead. Operation of a particular BOP function is then accomplished by directing hydraulic power from the control unit back and forth along two large bore lines to the appropriate operating piston.

This system uses the minimum number of controlling valves to direct the hydraulic fluid to the required function. It also enables the returning fluid to be returned to the control unit for further use.

For drilling operations, it is necessary to control larger, more complex BOP assemblies which are remotely located on the seabed. In this instance, direct control cannot be applied since the resulting control lines connecting the BOPs to the surface would be prohibitively large to handle. Reaction times would also be unacceptable due to the longer distances to the and the consequent. In order to overcome these problems indirect operating systems have been developed. There are two types — hydraulic and multiplex electro-hydraulic of which the indirect hydraulic system is by far the most common. INDIRECT HYDRAULIC SYSTEM This reduces the size of the control umbilical by splitting the hydraulic control functions into two:. Transmitting hydraulic power to the BOP down a large diameter line.

Transmitting hydraulic signals down smaller lines to pilot valves which in turn direct the operating power fluid to the appropriate BOP function. The pilot valves are located in control pods on the BOP stack. In order to provide a complete back-up of the subsea equipment there are two control pods — usually referred to as the blue and the yellow pods. No attempt is made to recover the hydraulic power fluid once it has been used to operate a function since this would increase the number of lines required in the umbilical. Instead the fluid is vented subsea from the control pod. Figure 49 - Hydraulic Hose Bundle MULTIPLEX ELECTRO-HYDRAULIC SYSTEM As greater water depths were encountered the problems of umbilical handling and reaction times became significant.

Shaffer Bop Pod Manual Line

In order to overcome them the hydraulic lines controlling the pilot valves were replaced by separate electrical cables which operate solenoid valves. These valves then send a hydraulic signal to the relevant pilot valve which in turn is actuated and directs power fluid to its associated BOP function.

Figure 49 - Hydraulic Hose Bundle MULTIPLEX ELECTRO-HYDRAULIC SYSTEM As greater water depths were encountered the problems of umbilical handling and reaction times became significant. In order to overcome them the hydraulic lines controlling the pilot valves were replaced by separate electrical cables which operate solenoid valves. These valves then send a hydraulic signal to the relevant pilot valve which in turn is actuated and directs power fluid to its associated BOP function. The time division multiplexing system provides simultaneous execution of commands and results in a relatively compact electrical umbilical. This typically consists of four power conductors, five conductors for signal transmission and additional back-up and instrumentation lines. With the armoured sheath the umbilical has a resulting diameter of some 1.5 inches with a weight of about 3 lb/ft in air.

ACOUSTIC SYSTEM In addition to either of the primary control methods mentioned above, the subsea BOP stack can also be equipped with an acoustic emergency back-up system. In principle this is similar to the other two systems but with the hydraulic or electrical commands to the pilot valves being replaced with acoustic signals. Being a purely back-up system the number of commands is limited to those which might be required in an absolute emergency.

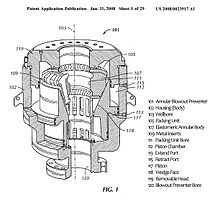

Each of these control systems is now described in greater detail. 1.16.3 Indirect Hydraulic BOP Control System The main manufacturers of control systems are Cameron Iron Works, NL Shaffer, Koomey and the Valvcon Division of Hydril. The NL Shaffer and Koomey systems will be discussed in detail to illustrate the general concept since these are probably the most common types. OVERVIEW Figure 50 shows the general arrangement. Fluid used to operate the functions on the BOP stack is delivered from the hydraulic power unit on command from the central hydraulic control manifold.

This contains the valves which direct pilot pressure to the pilot valves in the subsea control pods and which are operated either manually or by solenoid actuated air operators. In this way the manifold can be controlled remotely via the actuators from the master electric panel (usually located on the rig floor) or from an electric mini panel (located in a safe area). The system may include several remote mini-panels if desired.

An electric power pack with battery back-up provides an independent supply to the panels via the central control manifold. The pilot fluid is sent to the subsea control pods through individual, small diameter hoses bundled around the larger diameter hose which delivers the power fluid. In order to provide complete redundancy for the subsea portion of the control system there are two independent hydraulic hose bundles and two independent control pods. The hydraulic hose bundles (or umbilicals) are stored on two hose reels, each of which is equipped with a special manual control manifold so that certain stack functions can be operated whilst the stack is being run. Hydraulic jumper hose bundles connect the central hydraulic control manifold to the two hose reels.

Each umbilical is run over a special sheave and terminates in its control pod. For repair purposes each pod along with its umbilical can be retrieved and run independently of the BOP stack. In order to do this, the pod and umbilical is run on a wireline which is usually motion compensated. In some designs of control system, the umbilical is run attached to the riser in order to give it more support and reduce fatigue at hose connections. The pod is still attached to a wireline for retrieval purposes. This design has the advantage of not having to handle the umbilicals whenever the pod is pulled but has the disadvantage of requiring more subsea remote hydraulic connections.

Guidance of the pod is provided by the guidewires and guideframe as shown. The hydraulic fluid is prepared and stored under pressure in the. Some accumulators (usually two) are dedicated to storing fluid for use in the pilot line network and the remaining accumulators contain the fluid that is used to power the various BOP functions. Figure 50 - Hydraulic Subsea Control System General Arrangement The power fluid is routed to the subsea control valve which is located in the central hydraulic control manifold. The line to the non-selected pod is vented. When power fluid reaches the pod, it is combined with fluid stored at the same pressure in subsea accumulators, located on the BOP stack.

The pressure of the combined fluid is then reduced, to that required to operate the stack function, by a subsea regulator situated in the control pod. Adjustment of this regulator is performed from the surface via dedicated pilot and read-back lines in the hose bundle. Pilot fluid is always directed to both pods at the same time. When the pilot fluid for a particular function reaches each pod it lifts the spindle of its associated SPM (sub plate mounted) pilot valve. In the pod to which the power fluid has been sent this will allow the fluid to pass through the SPM valve and be routed to the stack function via a.

A summary of this operating sequence is shown in Figure 51. OPERATING SEQUENCE A more detailed description of the sequence of events that occur when a function is operated will now be given with reference to the flow diagrams in Figure 51, Figure 53, Figure 54 and Figure 55. Each piece of equipment on the BOP stack has a corresponding pilot control valve on the central hydraulic control manifold which actuates the appropriate SPM valve. The control valve is a four-way, three-position valve and can be functioned manually or by an air operator. Close Function In Figure 53 one of the BOP rams is being closed using the drillers master control panel. Pushing the 'close' button on this panel actuates the solenoid valves on the hydraulic manifold thus allowing air pressure to move the pilot control valve to the 'close' position.

The solenoid valve on the right in the diagram vents the other side of the air cylinder. With the pilot control valve in the 'close' position, pilot fluid at 3000 psi is sent down the umbilical to the RAMS CLOSE SPM valve in the subsea control pods. The pressure lifts the spindle in this valve so that it seals against the upper seat, thus blocking the vent. At the same time power fluid at its regulated pressure is allowed past the bottom of the spindle and into the valve block in the male and female sections of the control pod. From the bottom of the female section, the power fluid then travels through the shuttle valve to the 'close' side of the BOP ram cylinder. Simultaneous reciprocal action in the RAMS OPEN SPM valve vents the hydraulic fluid from the 'open' side of the BOP ram.

Thumb-tabbed chapters, numbered table of contents and an extensive index make it possible to locate the desired section quickly. Bold figure numbers make it easy to quickly match instructions with illustrations and photos. Cb500 t repair manual download.

Figure 51 - Operating Sequence - General Power Fluid at 3,000 psi Power Fluid at 1,500 psi Power Fluid (Vented) i pilot Fluid at 3,000 psi Pilot Fluid Vented) Rig Air Supply Vent Air Figure 52 - The above shading key is applied to the Subsea Control System block diagrams through this Section Figure 53 - Operating Sequence - Close Function Figure 54 - Operating Sequence - Block Function Figure 55 - Operating Sequence - Open Function Block Function The block function is used to vent a pilot control valve. By doing this individually on each valve a leak in the control system or the preventers can be located and isolated. By centring and venting all the valves when the accumulator unit is first being pressurised unintentional and inadvertent operation of the various other positions and functions can be eliminated. Referring to Figure 54, when the 'block' button is pressed, both the solenoid valves are actuated in such a way as to apply pressure to both sides of the air operator.

This causes the pilot control valve to be centred which then allows both the pilot 'open' and 'close' lines to be vented. The springs in both the then push the spindles down so that they seal against the bottom seats and block the flow of any power fluid through the valves.

At the same time this also vents both sides of the BOP ram operating cylinders. Open Function This sequence is the parallel opposite of the CLOSE function. As shown in Figure 55, when the 'open' button is pressed, the solenoid valves on the hydraulic control manifold are actuated and allow air pressure to move the operator on the pilot control valve to the 'open' position. The solenoid valve on the left in the diagram vents the 'close' side of the operating piston. The pilot fluid can then flow down to the subsea control pod where it lifts the spindle in the RAMS OPEN SPM valve thus blocking the vent and allowing power fluid to flow through the valve.

From the pod the power fluid travels through the 'open' shuttle valve to the 'open' sides of the BOP ram operating cylinders. Simultaneous reciprocal actions in the RAMS CLOSE SPM valve allows the fluid from the 'close' side of the operating cylinders to be vented. Control Fluid Circuit In addition to the control fluid circuits used to operate stack functions such as ram or annular preventers, the control system must also perform other functions such as control of subsea regulators, provide readback pressures, latch/unlatch the subsea control pods and charge the subsea accumulators. Figure 56 shows a typical control fluid circuit. The hydraulic fluid is mixed, pressurised and stored in accumulator bottles by the hydraulic power unit.

A pilot operated accumulator isolator valve is provided to allow the pumps to charge the subsea accumulators. When control fluid is used, it passes through a totalising flowmeter in the hydraulic control manifold and then through the pod selector valve which directs it to the chosen subsea pod. After passing through the jumper hose and the subsea hose bundle to the control pod, the fluid supplies the hydraulically operated subsea regulators.

These reduce the fluids pressure to that required to operate the particular BOP function desired. The fluid is also routed to a SPM valve in the pod which is controlled by the accumulator isolator valve on the hydraulic control manifold. In the open position this SPM valve allows the control fluid to charge the stack mounted accumulator bottles. This operation is described in more detail in Section Shuttle valves allow the bottles to be charged from either pod.

Figure 56 - Subsea Control System - Hydraulic Schematic Pilot Fluid Circuit The pilot valves in the subsea pods are controlled from the surface by means of control valves located in the hydraulic control manifold. These control valves can be operated either manually from the control manifold itself or remotely from an electrical panel via pneumatic solenoid valves. Any BOP stack function such as a failsafe valve, which requires pressure only to open or close it is called a 2-postion function.

There is an 'operate' position and a 'vent' position. The latter position is used to release pressure from the operating side of the pilot valve. Figure 57 shows a typical 2-position function pilot circuit. The control valve, a%', four-way manipulator valve, can be controlled from a remote panel via the two solenoid valves which can place the valve either in the 'open' or 'vent' positions. A pressure switch connected to the discharge line of the control valve is activated when a pilot signal is present and lights up the appropriate lamp on the control panel. In the 'open' position the pilot signal is transmitted to the subsea control pods where it operates its associated pilot valve which then allows the power fluid to flow through the selected pod to the BOP function.

A BOP stack function requiring pressure to both open and close is called a 3-position function. The hydraulic pilot fluid circuit for a 3-position function is shown in Figure 58. It requires the use of three solenoid valves, the 'block' solenoid valve being used in conjunction with two shuttle valves in order to centre the control valve. A pressure switch is connected to each discharge line of the control valve and will transmit a signal to the appropriate control panel lamp whenever a pilot circuit is as described above. The main components of the control system and some of the other operating sequences are now described in more detail. Figure 57 - Pilot Fluid Circuit (2-Position Function) Figure 58 - Pilot Fluid Circuit (3-Position Function) Stack Function Stack Function Figure 58 - Pilot Fluid Circuit (3-Position Function) HYDRAULIC POWER UNIT This unit contains the mixing system, high pressure pumps and accumulator banks as shown in Figure 56. Mixing System The hydraulic power unit supplies hydraulic fluid to the entire control system.

Shaffer Bop Schematics

It requires fresh water, soluble oil, glycol (for freeze protection), compressed air and electrical power for operation. Two small reservoirs contain the soluble oil and glycol which are automatically blended with fresh water to make up the hydraulic fluid which is then stored in a large reservoir known as the mixed fluid tank.

Shaffer Bop Manual

Since the control system is an 'open' one in that the used hydraulic power fluid is vented into the sea, the type of soluble oil used must be completely biodegradable. Additives to prevent bacteria growth and to inhibit corrosion are also frequently included in the mix water. The soluble oil reservoir has a capacity of at least 110 gal whilst the mix fluid tank should be capable of holding sufficient fluid to charge the system accumulators from their pre-charge condition to their maximum operating pressure. All the tanks are fitted with sight glasses and a low-level alarm system which activates a warning light and horn on the control panels. The proper mixing fluid ratio is maintained by air operated hydraulic pumps, a water pressure regulator, a double acting motor valve and a water flow rate indicator.

A reservoir float switch is used to control operation of the mixing system in order to maintain the correct level of fluid and to ensure a continued supply for the control system. Water/additive concentrations can be adjusted by setting the mixing pump to run at the appropriate rate. A minimum rig water supply pressure of 25 psi is typically required for the correct operation of the mixing system and to provide a fluid supply at least equal to the rate at which mix fluid is drawn from the tank by the high pressure pumps. High Pressure Pumps These are the pumps which take the fluid from the mix tank and transfer it to the accumulator bottles, under pressure, where it is stored ready for use by the system. Typically, three air powered and two electrically power pumps are used. During normal operation the electric pumps are used to recharge the system.

However is these cannot keep up with demand, or fail in some way, then the air powered pumps can assist or take over completely. The electric pump assemblies consist of a heavy duty triplex reciprocating pluger pump with a chain and sprocket drive and powered by an explosion-proof motor. Pump capacity should be such that they can charge the system accumulators from their pre-charge condition to their maximum operating pressure in less that 15 minutes.

See Section below for calculations involving accumulator and charging pump capacities. One of the three air powered pumps is usually employed purely for charging the pilot fluid accumulators. The pumps are connected to rig air which passes through a filter and a lubricator on the pump unit before use. If the rig air supply fails, these pumps are usually also connected to a dedicated stand-by air compressor or to precharged stand-by air pressure vessels. Both types of pumps are manifolded so that each one can be isolated, for maintenance purposes, without interfering with the operation of the other.

Both types of pump are equipped with pressure switches to start and stop them at selected pressures. With the fluid stored in the accumulators at 3000 psi, the electric pumps are usually set to start when the pressure drops to below 2700 psi and the air powered pumps would cut in when the pressure drops to 2600 psi. If for some reason either set of pumps failed to shut down when the pressure reached 3000 psi then a relief valve (normally set at 3500 psi) would vent the fluid back to the mix tank when its pre-set pressure is reached. Two 40 micron filters ensure that the fluid is clean and fit for use before it is stored in the accumulators. They are connected in parallel so that either one can be isolated for maintenance without requiring a pump to be shut down. ACCUMULATORS Accumulators are the 'batteries' of the control system, they allow large volumes of hydraulic fluid to be stored, ready for immediate use.

Due to space and weight considerations most of the accumulator capacity is located at the surface as part of the hydraulic control unit. However, as much as possible is deployed subsea since in this position it is closer to stack functions and can provide a more acceptable response time. Subsea accumulator bottles also act as surge dampeners for annular preventers during stripping operations. Although subsea accumulators offer very definite advantages, they do complicate the control system in the following ways:. Provision has to be made to recharge them immediately, via the power fluid line in the umbilical, once any fluid has been displaced from them. It must be possible to isolate them whilst running or retrieving the lower marine riser package or for identifying or controlling a leak in the system.

Accumulators store hydraulic energy for use even if high pressure pumping capacity is lost and can instantly supply fluid at flow rates much greater than a system relying purely on pumps. The energy is stored by compressing nitrogen as the hydraulic fluid is forced into the accumulator. When required for use, the stored energy in the nitrogen is then used to expel the fluid. Nitrogen is used as it is readily available and is relatively inert.

CENTRAL HYDRAULIC CONTROL MANIFOLD The central hydraulic control manifold contains all the equipment necessary to control the pilot valves and regulators on the subsea pods and also pressure gauges to indicate the general status of the system. It is capable of being operated remotely from one of several remote panels and so is equipped with all the necessary electro-pneumatic solenoid valves, pressure switches and transducers in an explosion-proof enclosure. The manifold essentially performs four functions:.

Pod selection. Pilot manipulator valve control. Regulator control. Pressure readback display Pod Selection The pod selector valve is a 1' four-way manipulator valve which directs the power fluid to the active pod via the hydraulic junction box and umbilical, and vents the inactive pod to the mixed fluid tank. A 1' positive displacement flowmeter provides an accurate measurement to the fluid used to actuate each stack function. Figure 59 illustrates Surface Selector and Subsea Manipulator Valves.

Pilot Valve Control Pilot valve control is achieved by using%', 3-position, 4-way manipulator valves which are equipped with air operators for remote control. The hydraulic signal from each of these valves goes to both quick disconnect junction boxes, through both umbilical hoses and actuates the pilot SPM valves on both the active and inactive pods as shown in Figure 57 and Figure 58. Figure 60 shows a typical control valve arrangement on the control manifold. The hydraulic fluid supply goes through a check valve and charges two pilot fluid accumulator bottles.

In this way the pilot system is protected from pressure drops when power fluid is quickly consumed from the main accumulator banks.